In general, the gate control in hydraulic engineering is mostly the gate electrical control, gate position detection and automatic control using independent devices, electrical circuit is more complex, information is not matched, daily operation management and maintenance is more difficult.

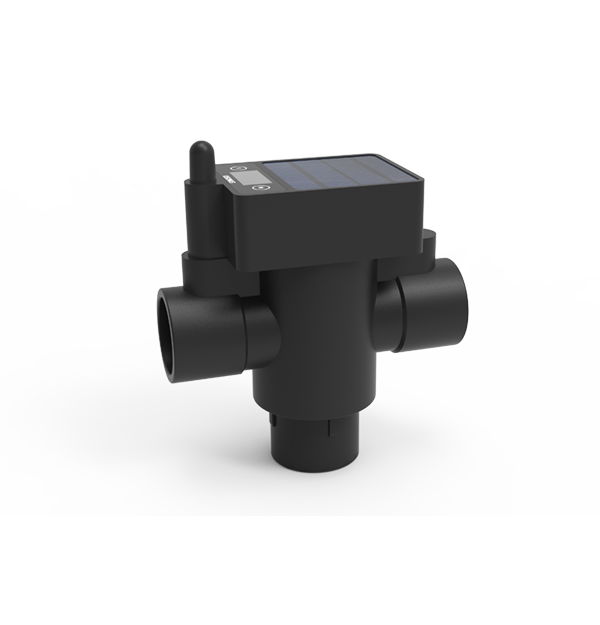

In view of these situations, SINOSO technology developed COCON GT gate intelligent measurement and control integrated equipment. The device is a kind of intelligent device integrating mechanical, electronic and sensor technology. It has advanced working principle, reliable operation, high detection accuracy, strong anti-interference ability and many other advantages, which provides reliable guarantee for the safe operation of the gate.

COCON GT gate intelligent measurement and control integrated equipment can not only monitor the opening of the gate online, but also control the gate lifting. At the same time, it can also provide comprehensive online protection for the gate lifting motor. COCON GT gate intelligent measurement and control integrated equipment is convenient to install, simple wiring, can simplify the electrical secondary circuit wiring in the process of use, can set a variety of motor protection parameters through the humanized display interface, online display gate lifting motor operation data and gate opening, at the same time can be simple and flexible zero calibration and gate opening setting. It not only provides programmable I/O channel, but also provides standard communication interface, communication interface supports a variety of communication protocols, can be the gate various operating parameters information for remote transmission and accept remote control commands. COCON GT gate intelligent measurement and control integrated equipment has been listed as a key new technology product for promotion by the Ministry of Water Resources.

Software copyright Name: Embedded software V1.0 of SINOSO Gate intelligent measurement and control integrated equipment.

- Operating environment condition

- Gate opening sensor

- Working power supply

- Starting control

- Display operation unit and communication interface

- Programmable I/O interface

- Dimension parameter

- Protection function

|

Installation location |

Indoor (outdoor installation needs to be customized) |

|

Maximum ambient temperature |

55℃ |

|

Minimum ambient temperature |

-20℃ |

|

Altitude |

≦4000m |

|

Humidity |

≦95% |

|

Repetition accuracy |

±2BIT (Actual accuracy is related to installation accuracy and shaft concentricity) |

|

Allowable speed |

2400 RPM (12, 25 bits), 1000 RPM (16, 25 bits) |

|

Blackout preservation |

Within 4096 laps absolutely, power outage does not affect position preservation |

|

Contour feature |

Clamping flange or synchronous flange, metal case, sealed double bearing construction |

|

Protection class |

IP65 |

|

Three phase four wire system |

AC 380V(±15%) |

|

frequency |

50~60HZ(±5%) |

|

Opening and closing motor power |

< 10KW, direct start ≧10KW, soft start |

|

Display operation unit and communication interface |

Select LCD digital display operating unit, 1 RS485 MODBUS RTU Industrial LCD tablet computer, 1 TCP/IP Ethernet interface Two RS485 MODBUS Rtus |

|

Switching input |

12 way, relay isolation, AC 220V |

|

Switching output |

6-way, relay isolation, passive contact (10A) output |

|

Analog input |

4 channels, 4-20 MA input, all electrical isolation |

|

Analog volume output |

2 channels, 4-20mA output, all electrical isolation |

|

Equipment dimensions |

650mm(width) * 800mm(height) * 270mm(depth) |

|

Installation mode |

Wall mounting |

|

Quick break protection |

COCON GT provides quick-break protection against instantaneous current changes caused by short circuit, etc. The range of quick-break current (10-14) *ln, and the piecework capacity is 70kA. |

|

Overload protection |

COCON GT monitors the used heat capacity of the motor. When the heat capacity reaches 100%, overload tripping will be caused. The heat capacity is calculated by selecting an overload curve for l squared t. Current true RMS (RMS) detection ensures a correct response to the effect of harmonics on heating. There are 8 different overload curves to choose from. |

|

Blocking protection |

COCON GT monitors the state of the host in real time. In the case of overcurrent caused by the gate mechanical equipment being stuck, when the current exceeds the clogging trip value, the device will issue the tripping command through a certain delay (or immediately). |

|

Phase unbalance protection |

COCON GT monitors the percentage of motor phase current unbalance. If the phase current imbalance is greater than 15%, and the duration exceeds the set value will alarm; If the phase current imbalance exceeds 30%, and the duration exceeds a fixed value, it will trip; If the phase imbalance is greater than 60% (missing phase), it will cause immediate tripping. |

|

Low/overvoltage protection |

Provide low voltage and overvoltage alarm and tripping function, its fixed value can be set according to the need, this function can be put in or locked according to the need. |

|

Enable accelerated timeout protection |

When the main engine starts, if it does not fall below the rated current of the motor within the set time, it will issue the start acceleration timeout alarm and trip. The function can be put in or locked according to the need. |

|

Ground/leakage protection |

COCON GT detects zero sequence current in real time to protect the ground/leakage fault of the host. |

|

Contactor failure alarm |

The device always monitors the status of the bypass contactor when issuing start and stop commands. Once the contactor does not change its state (split or split), a control loop break or contactor contact welding alarm is generated. |