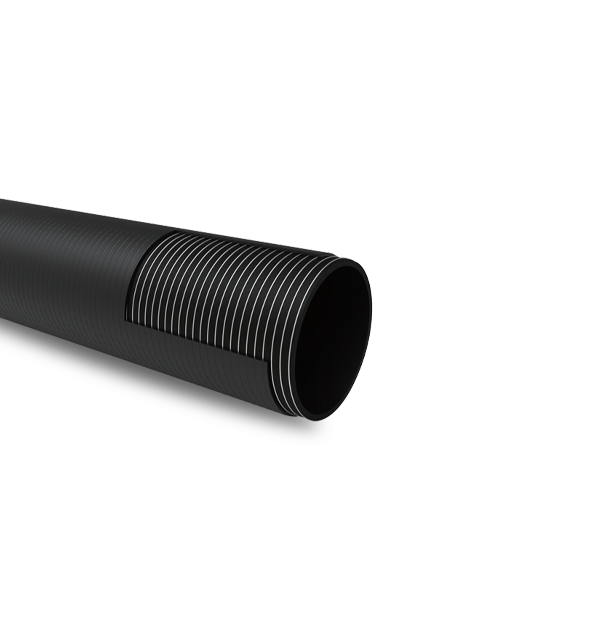

SINOSO series reinforced polyethylene (PE) pipe is a national high-tech research (" 863 "program) achievement. It combines high-strength steel and PE plastic into one, giving full play to the physical, chemical and mechanical advantages of steel and plastic, and complementary properties to form a new type of green pipe with the advantages of both steel and PE pipe. In keeping the PE pipe clean health, no corrosion and good flexibility, but also has the high pressure resistance of the steel pipe.

When the pipe is in the same caliber and the same flow, the water and power consumption is reduced by more than 30% compared with ordinary PE plastic pipe, which is an ideal energy-saving and emission reduction product. Especially suitable for farmland irrigation and agricultural efficient water-saving irrigation, drinking water supply in villages and towns, municipal water supply and drainage and mine, oil field and other water transmission projects.

SINOSO series reinforced polyethylene (PE) pipes passed the ministerial new product production appraisal and won the second prize of ministerial Science and Technology Progress.

- Certification and certificate

- Product classification and specification

- Design considerations

- Nominal pressure

- Pipe marking

- Physical and mechanical properties of pipes

|

Quality management system certification

|

|

Occupational health and safety management system certification |

|

|

|

|

Sanitary approval of domestic products related to drinking water sanitation safety in Jiangsu Province

|

|

|

Pipe appearance, flat test, hydraulic test, instantaneous blasting and other mechanical properties testing

When the temperature of the conveying medium is higher than 20°, the nominal pressure should be multiplied by the pressure coefficient listed in the following table to obtain the pressure grade at the temperature.

|

Pressure coefficient table |

|||||

|

Medium temperatureT(℃) |

0<T≤20 |

20<T<25 |

25<T≤30 |

30<T≤35 |

35<T≤40 |

|

Pressure coefficient |

1.0 |

0.93 |

0.87 |

0.80 |

0.74 |

The water head loss along the pipe (including the joint of the same diameter) can be calculated according to the following formula:

△H=1.10x10⁵·Q¹·⁸⁵²·L/D⁴·⁸⁷¹

Where :△H- head loss along the path (m); Q- flow rate (m³/h); L- Pipe length (m); D- Tube diameter (mm)

Set the inlet and exhaust valves at appropriate positions;

The pier is arranged in the reducer joint, tee, elbow, valve, plug and other parts;

The calculation formula of water head loss along the pipe adopts GB50015 standard, and the calculation results are basically consistent.

Note: The marked length of the pipe is 6m, 9m and 12m. The default length is 9m. Other specifications are subject to negotiation between the supplier and the demand.The length error is ±2‰.

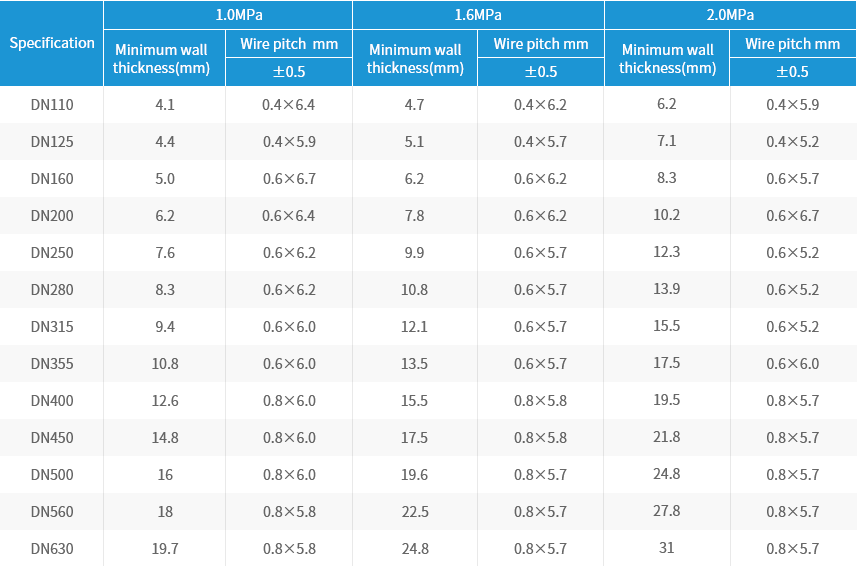

Tubing with nominal pressure (MPa) can be divided into 0.4, 0.6, 0.8, 1.0, 1.6 and 2.0 grades. Tubing with nominal pressure of 22.0MPa is produced according to the agreement between the supply and demand parties.

Note: In the case of drainage pipe, the last is ring steel, the other is nominal pressure.

Example 1: PESJ200-1.0 denotes reinforced polyethylene (PE) feedwater pipe with a nominal diameter of 200mm and a nominal pressure of 1.0Mpa.

Example 2: PS-P200-SN4 represents a reinforced polyethylene (PE) drainage pipe with a nominal diameter of 200mm and ring stiffness of SN4.

Mechanical properties of water supply pipe

|

Test project |

Technical requirement |

Test method |

|

Hydrostatic test |

Water supply pipe: 20°C, 1.5 times, 100h, no rupture, no leakage |

Measured according to GB/T6111-2018 |

|

Blasting test |

Water supply pipe :≥3 times nominal pressure |

Measured according to GB/T6111-2018 |

|

Compression cracking stability |

Pressure to the outer diameter of pipe 50%, no crackReinforcement and plastic do not detangle |

Measured according to GB/T647-2015 |

Mechanical properties of irrigation pipe

|

Test project |

Technical requirement |

Test method |

|

Hydrostatic test |

Water supply pipe: 20°C, 1.5 times, 1h, no rupture, no leakage |

Measured according to GB/T6111-2018 |

|

Blasting test |

Irrigation pipe :≥2.5 times nominal pressure |

Measured according to GB/T6111-2018 |

|

Compression cracking stability |

Pressure to the outer diameter of pipe 50%, no crackReinforcement and plastic do not detangle |

Measured according to GB/T647-2015 |

Mechanical properties of drainage pipes

|

Test item |

Technical requirement |

Test method |

|

|

Ring stiffness (kN/m²) |

SN2 |

≥2 |

Measured according to GB/T9647-2015 |

|

SN4 |

≥4 |

Measured according to GB/T9647-2015 |

|

|

SN6.3 |

≥6.3 |

||

|

SN8 |

≥8 |

||

|

SN12.5 |

≥12.5 |

||

|

SN16 |

≥16 |

||

|

Ring flexibility |

The specimen is smooth, no reverse bending, no fracture, the specimen tear along the rib cutting is allowed to be less than 0.075dn or 75mm(take the smaller value) |

Measured according to GB/T9647-2015 |

|

|

Longitudinal retraction rate |

≤3%,The pipe shall have no delamination and no cracking |

Measured according to GB/T6671-2018 |

|